MECAVIT offers immediate delivery of a wide range of standard screws and the production of special screws made with various types of high resistance carbon steel and stainless steel.

» Company » Production

» Company » Production

ProduCTION |

Company » History » Production » Certification » Corporate videos » Virtual tour » |

MECAVIT employs only certified quality steel after that strict controls are made. Automated production lines transform the raw material into screws and parts according to unified standards or to customized specifications.

Unified screws

The standard production is compliant with the DIN, UNI, ISO standards and international parameters.

Special screws

In the production of special screws our technical staff activates the production process using CAD both operationally translating the customer’s design and developing targeted solutions to specific needs such as mechanical resistance or corrosion requirements.

Wire rod preparation |

Tool shop department |

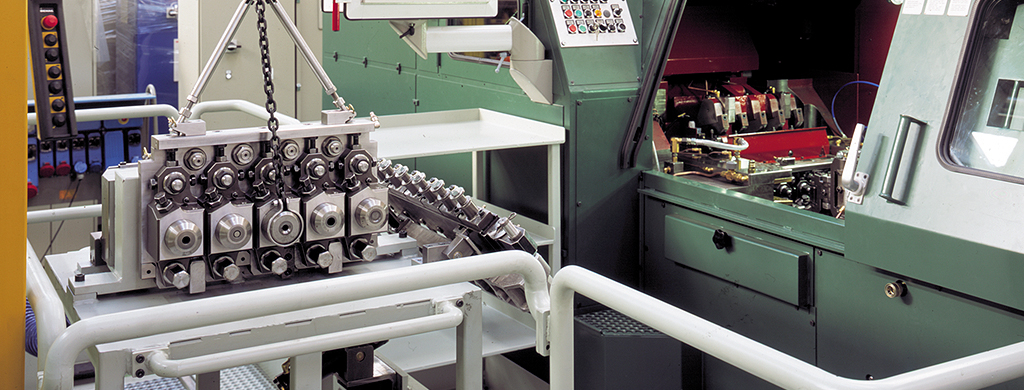

Cold Forming |

Thread Rolling |

|

Wire rod preparation line for mechanical pickling and polymerization treatment . |

|

The automated lines transform the wire rods into screws by cold forging according to standards or according to the customer’s drawing. The highly industrialized production process starts using modern multi-step machines equipped with computerized control systems on machine board. |

The highly industrialized production process starts using modern multi-step machines equipped with computerized control systems on machine board. |

|

|

|

|

Sorting department - Second Operations |

Heat treatment |

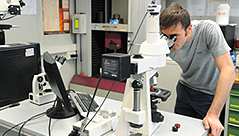

Quality |

Logistics - Warehouse |

|

Mecavit is equipped with the most modern machines that can sort 100% of the product on dimensional criteria, presence of cracks and socket depth. Mecavit utilizes some last generation production technologies to perform secondary mechanical machining on forged products. |

To keep its production process flexible and independent, Mecavit has installed an automated line for the heat treatment. The modern belt conveyor furnace is operated and controlled by a computerized system that allows also the remote control of the line. |

Mecavit can supply any certificates requested in the automotive field. The internal lab, which is technologically advanced, is equipped with all instruments necessary to carry out the requested inspections and assure the quality of the product. |

The logistic of the semifinished products and of the whole production process is handled by means of modern computerized devices that assure the immediate traceability of each batch during the production process and over time. The 4000 pallets stock gives Mecavit the possibility of being flexible and fast in delivering the goods. |

|

|

|

|